From standalone depaneling machines to fully integrated in-line systems, we provide reliable PCB depaneling solutions designed to meet the demands of modern SMT production. Our solutions focus on precision, low stress, automation readiness, and long-term production stability.

We offer a complete range of PCB depaneling solutions, engineered to address different production environments, board designs, and manufacturing challenges.

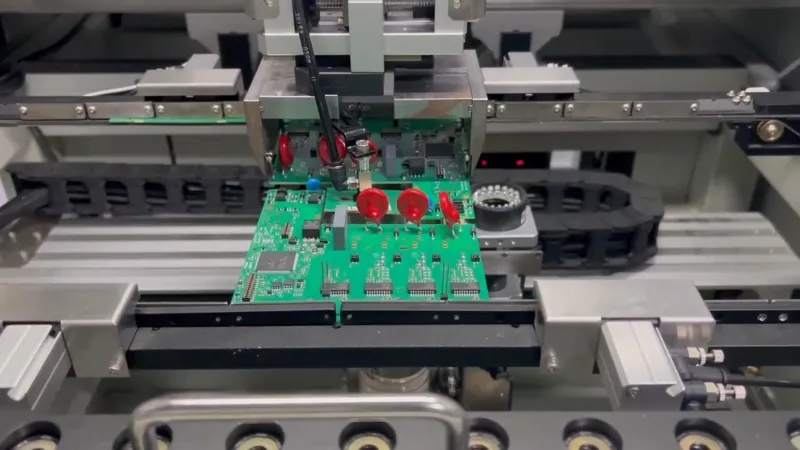

Designed for continuous SMT production, our in-line depaneling systems seamlessly connect with upstream and downstream equipment, enabling automated handling, higher throughput, and reduced labor dependency.

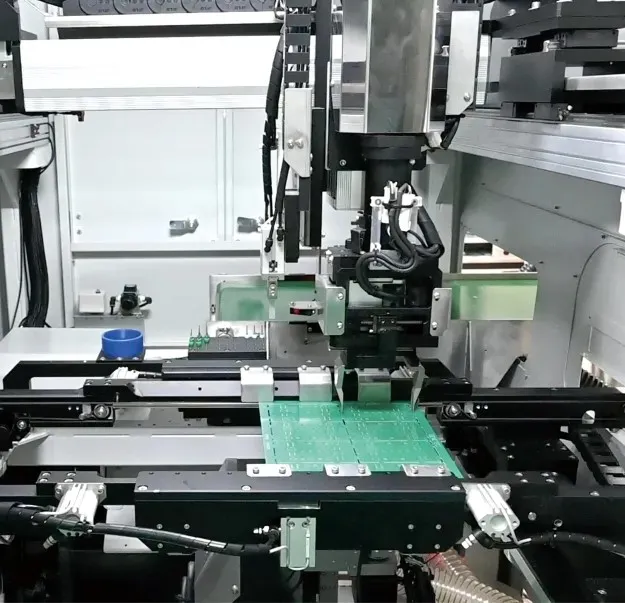

By eliminating traditional jigs, our fixture-free solutions allow fast product changeovers and greater flexibility across multiple PCB designs, improving overall production efficiency.

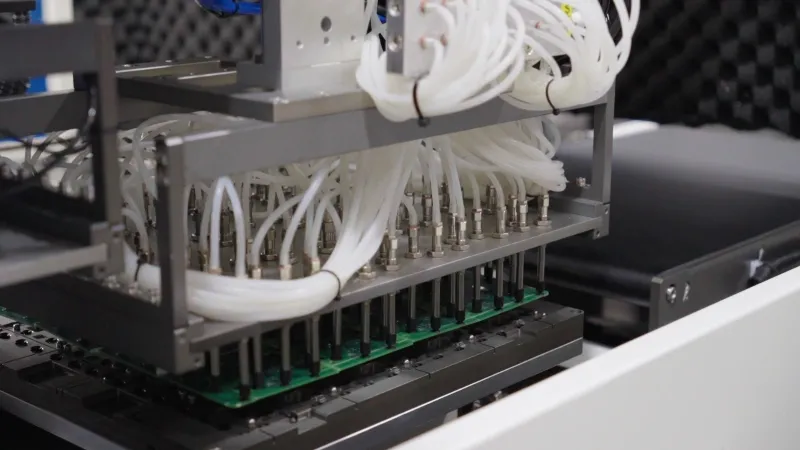

For PCBAs with tall or densely populated components, we provide bottom depaneling and gripper-based solutions that minimize mechanical stress and protect sensitive assemblies.

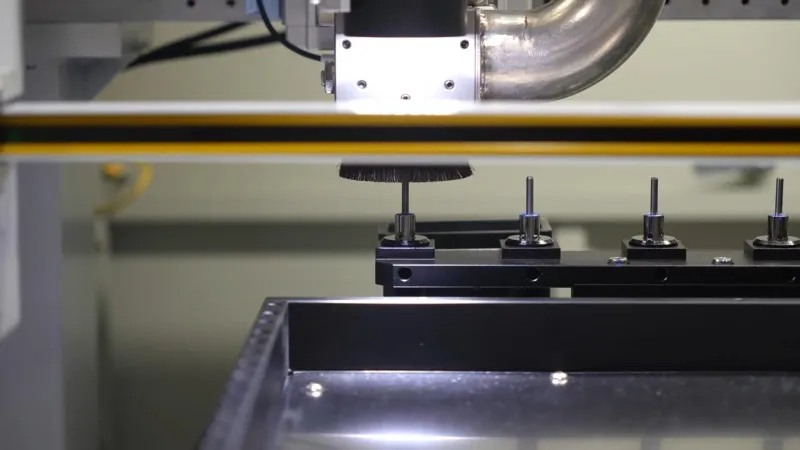

Using advanced routing, laser, and vision-guided technologies, our systems deliver clean edges and consistent accuracy while reducing the risk of micro-cracks and component damage.

Optimized for speed, stability, and repeatability, these solutions are ideal for mass production environments requiring reliable performance over extended operating cycles.

Our equipment supports barcode tracking, MES connectivity, and process monitoring, enabling data-driven production and seamless integration into smart manufacturing systems.

Our depaneling solutions are widely used across multiple electronics manufacturing sectors.

Designed for high-throughput SMT and EMS environments, our depaneling solutions support fully in-line operation, stable takt time, and automated material handling.

Vision-guided cutting, fixture-free configurations, and flexible loading/unloading options ensure seamless integration with modern SMT lines while reducing manual intervention and downtime.

Automotive electronics demand consistency, traceability, and long-term reliability.

Our depaneling systems deliver repeatable precision and low-stress cutting, supporting barcode tracking and MES integration to meet strict automotive quality and process control requirements.

For medical devices and other high-reliability applications, component protection is critical.

We provide low-stress depaneling solutions that minimize mechanical impact, reduce the risk of micro-cracks, and ensure clean, controlled separation for sensitive PCB assemblies.

Consumer electronics production requires speed, flexibility, and frequent product changeovers.

Our solutions enable fast configuration changes, high cutting efficiency, and consistent edge quality, supporting mass production while maintaining stable yield rates.

Industrial control and power electronics often involve thicker boards and complex layouts.

Our robust depaneling systems are engineered for stable cutting performance, long operating cycles, and reliable processing of demanding PCB designs in industrial environments.

We help manufacturers overcome common depaneling challenges through targeted engineering solutions.

→ Gripper-based bottom depaneling systems designed to avoid component interference.

→ Fixture-free designs with software-based configuration.

→ Vision-guided precision cutting and optimized motion control.

Our engineers analyze PCB design, materials, and production requirements to recommend the most effective depaneling solution.

We offer customized mechanical design, software configuration, and automation integration tailored to your production line.

On-site or remote installation support, along with structured training for operators and maintenance personnel.

Fast-response technical assistance, spare parts supply, and continuous support to keep your production running smoothly.

Because we know that even the best products are only as strong as the people behind them. That’s why we provide 24/7 expert technical support—whenever and wherever you need it.

Ready to Upgrade Your PCB Depaneling Process?

Leo Xu

sales@seprays.com

Leo Xu

Not sure where to start? We'd love to help you!

Powered by Elementor