Founded in Taiwan in 1993, SEEZM-TEC focuses on technological R&D and innovation. In 2002, it established a branch in Dongguan (upgraded and reorganized into a subsidiary in 2013), fully responsible for R&D, production, sales, and after-sales technical training services, ensuring rapid response and comprehensive support to customer needs. To further expand production, in 2003, it purchased nearly 20 acres of land in Zhejiang Province and established a 20,000 square meter modern industrial plant, increasing production capacity and manufacturing capabilities.

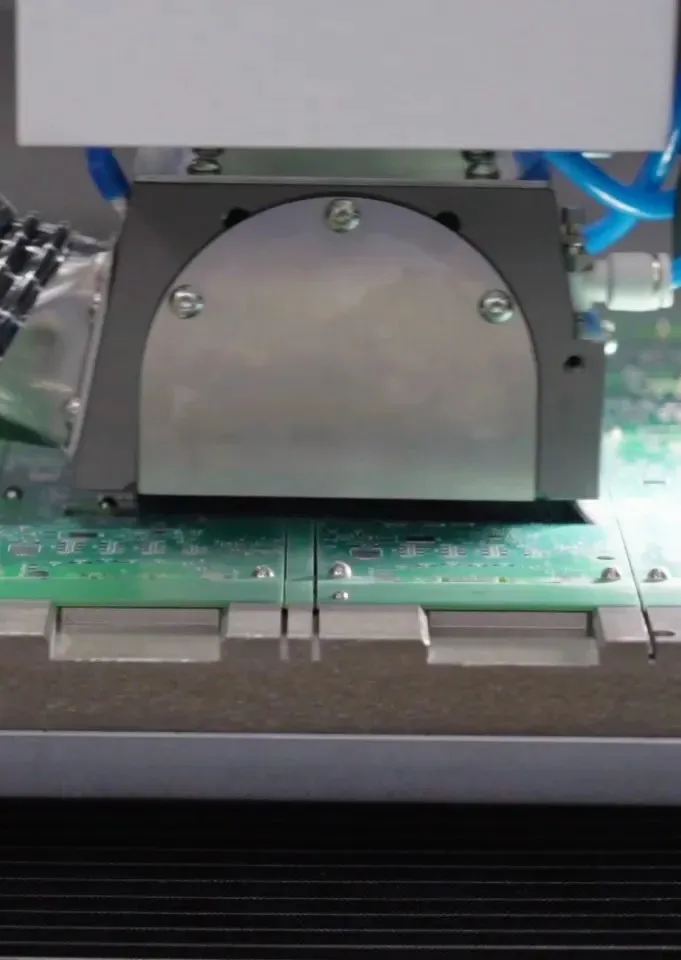

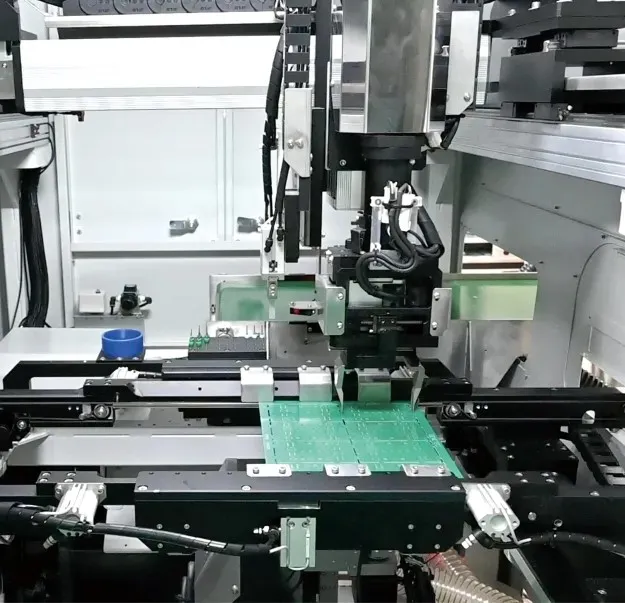

SEEZM-TEC has been dedicated to the PCB/FPC depaneling field for over 30 years. Its main products include milling cutter depanelers, laser depanelers, V-groove depanelers, and stamping depanelers, as well as automated loading and unloading solutions for the front and rear ends of depaneling, including plate placement. It is a high-tech enterprise integrating R&D, production, sales, and service.

SEEZM-TEC provides a complete line of equipment services to Fortune Global 500 and China’s Top 500 companies, including Foxconn, Flextronics, State Grid, Luxshare, Compal, Wistron, Bosch, China Electronics, Quanta Computer, CRRC Corporation Limited, China Aerospace Science and Technology Corporation, OPPO, and ZTE, as well as small and medium-sized enterprises. SEEZM-TEC complete panel separation lines are widely used in factories both domestically and internationally.

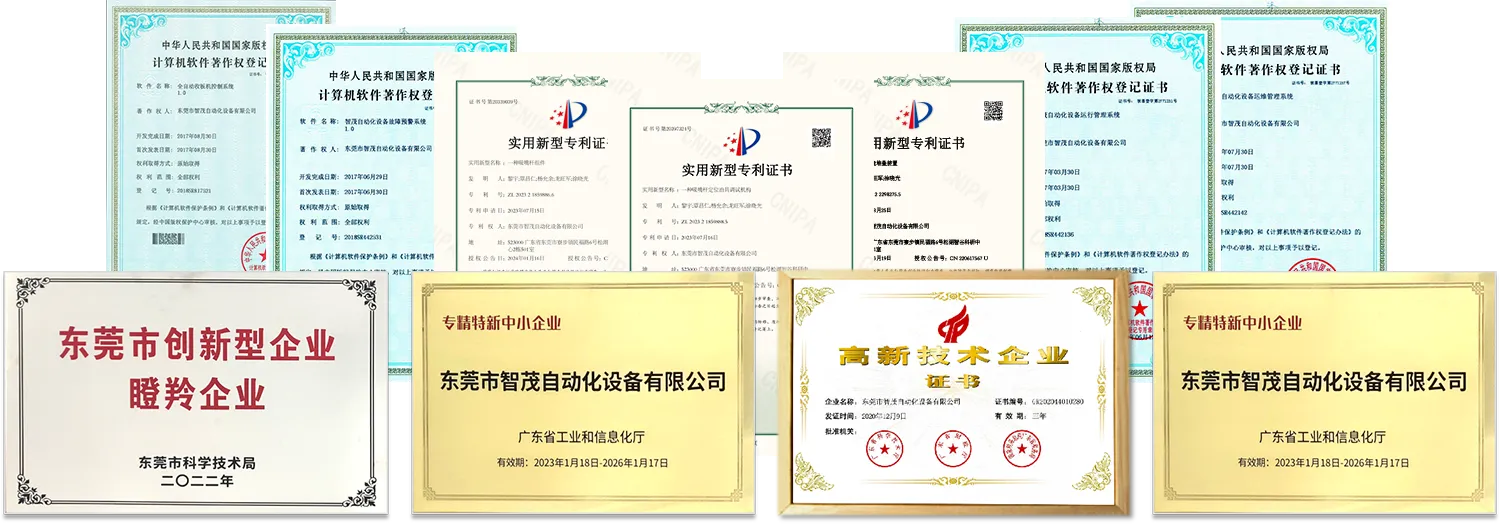

The company is ISO9001, ISO14001, and ISO45001 certified, holds CE certification, and owns over 100 hardware and software patents. It operates two modern factories covering over 26,000 square meters in mainland China and has service locations in nine cities across China, providing nationwide after-sales service. Sales and service locations in 31 countries worldwide provide timely customer service.

PCB Depaneling Total Solution

Countries & Regions

Years of experience in SMT industrial equipment manufacturing

Patents & Certificates

Modern factory building

We believe that every cut matters.

In modern electronics manufacturing, precision is not optional — it is the foundation of reliability. That is why we design our PCB depaneling machines with a single philosophy: deliver consistent accuracy, protect every component, and ensure long-term production stability.

We combine engineering discipline, real-world factory experience, and customer-driven innovation to build machines that enhance productivity while reducing stress, defects, and maintenance.

Every cut matters. Precision is not optional in modern electronics — it is the foundation of product reliability and long-term performance.

We design our machines to deliver consistent accuracy while protecting sensitive components and ensuring stable production in real SMT environments.

Pilates is about more than just movement—it’s about awareness, breath, and control.

Hear the experience of our happy clients

Advanced depaneling technologies are designed to deliver consistent accuracy while minimizing mechanical and thermal stress on PCB assemblies.

Engineering solutions built for seamless integration into automated SMT lines and smart factory environments.

Every machine is developed, tested, and validated through real production environments to ensure long-term reliability.

Committed to education, community support, and employee well-being, we believe sustainable success is built on responsibility and trust.

A people-centered culture built on collaboration, trust, and shared experiences — where teamwork extends beyond the workplace.

Because we know that even the best products are only as strong as the people behind them. That’s why we provide 24/7 expert technical support—whenever and wherever you need it.

Ready to Upgrade Your PCB Depaneling Process?

Leo Xu

sales@seprays.com

Leo Xu

Not sure where to start? We'd love to help you!

Powered by Elementor